I、the methods summary

Will stir the even water sample to put in evaporating dish in the known weight, moves in 103~105℃ the drying oven evaporation

to the constant weight, increases the weight namely to be heavy for the total solid. The other will stir the water to a known

weight of the glass fiber filter filtration, filter into 103 ~ 105 ℃ oven dried to constant weight,its increase the weight of

suspended solids is the weight. Total solid heavy subtract to suspend solid heavy or water kind first after glass fiber filter a slice

of percolation, it filters a liquid again according to total solid examination the step carry on, namely the total dissolved solid is

heavy.

II、Applicable scope

This method is applicable to drinking water fluid matter, the drinking water headwaters fluid matter, surface water, groundwater,

liquid waste, discard(dirty) in the water and the sea area water quality the total solid, the suspended solid and the total dissolved

solid (total dissolved solid quantity or total dissolved solid thing) the determination.

III、Disturbance

(A)In water kind if contain a great deal of calcium, magnesium and chloride and or vitriol, easily affect by damp , so need the

aridity in longer dry time, adequacy keep a method and quickly weigh.。

(B)Large floating objects in water samples, and other lumps should be removed in advance; if the oil slick or floating fat, should

scatter beforehand by the mixer takes mix and then sampled

(C)If on the evaporating dish has the massive solids, possibly will form the absorbing water hard lump, therefore in this method

limit sample content of the solid should be lower than 200 mg.

(D)Due to the obstruction of the filter makes filter time prolonged, lead to adsorption of colloidal particles and suspended solid

data on the high side.

(E)When measurement suspended solid, if water kind has a great deal of dissolved solids, flushed with plenty of water filter a

slice, can remove the deliquescence solid of attaching . .(note 1)

(F)Reduce the number of open dryer, to prevent moisture from entering.

(G)Samples with high fat content, as it is difficult drying to constant weight, the results will affect the accuracy.

IV、Equipment and material

(A)Evaporation pan:100 mls, the material can be following one of 3 kinds

1.Porcelain and ceramics, diameter 90 mm.

2.Platinum or metal material won't cause a reaction in water samples.

3.Glass with high silicon content.

(B)Water bathes slot.

(C)Desiccator.

(D)Oven: temperature control in 103~105℃.

(E)Analytical balance: can be refined to 0.1 mg.

(F)Teflon coating of the magnet.

(G)Wide mouth pipette or graduated cylinder.

(H)Glass fiber filter: Whatman grade 934AH; Pall type A/E; MilliporeType AP-40; E-D Scientific Specialties grade 161Or

the same class.

(I)Filters: one of the following three forms

1.Thin-film filter funnel.

2.Gooch Crucible: 40 mL or 25 mL.

3. Report of 40~60 of μ m aperture filter plate filters.

(J)Ventilation device.

(K)Disc: aluminum or stainless steel.

V、Reagent

Reagent water: Goes to the ion distilled water.

VI、Sampling and preservation

Must use the glass bottle of anti- acidity while sampling or plastic bottle of, the in order to prevent suspends solid to adsorb on

the machine wall, all should be kept to the dark place of 4 ℃ before analyzing to avoid solid microorganism decomposition.

As soon as possible examine after sampling, grow the expiry day as 7 days most .

VII、Step

(A)Total solid

1.Preparation of the evaporating dish: Evaporating dish of the cleaning will put in 103~105℃ in the drying oven 1 hour,

moves in the water extractor to cool spare, before the use, only then weighing.

2.After first sample intensive mixing, (note 2) moves by the pipette or the graduated cylinder takes the solid content

approximately during 2.5~200 mg the water sample quantity evaporating dish in already the weighing (note 3), and

evaporation in the water bath trough or the drying oven, the evaporation process must adjust temperature is lower

than the boiling point 2℃ to avoid the water sample bumping. Move in the process of taking the samples shall be in

mix evenly . If has the necessity to be possible dry following to join water sample of the quota in the sample to avoid

the solid content too few affecting the result. Move the evaporation pan into 103~ after 105 ℃ an hours inside the

ovens, move it into again inside the desiccator, cooling behind weigh. Repeat above-mentioned dry, cool off, dry and

weigh a step until the Heng is heavy.(before or after two times of weight bad within the scope of 0.5 mg)While

weighing dry sample, carefully due to exposure to air and decomposition caused by the weight of the sample changes.

(B)Suspend solid

1.The glass fiber filters the preparation of slice:Will filter a slice of wrinkly side with an upward exposure shop in filter

equip up, open to gasp device, continuous each try water to flush by 20 mls 3 times, continue to gasp to remove all

humidities.Will filter a slice to dismantle to place on the disk, move into oven to dry by 103~105 ℃ for an hour, again

take out it to move into to cool off in the desiccator, need its Heng to take into to weigh after weighing.Repeat

above-mentioned dry, cool off, dry, the step weighed, until before or after two times of the weight is bad within the

scope of 0.5 mg. Will contain the disk of filtering the slice Be kept to inside the desiccator to provide for use.

2.Filter the choice of slice and amount of sample:Sample quantity with can acquire the solid of of the 2.5-200 mg heavy is

proper(note 3), as solid content too low then can increase a sample physical volume to 1 liter.(note 4)If filter time for

more than longer than 10 minutes, then can enlarge to filter the size of the slice or the physical volume of the decrease

sample.

3.Sample analysis: weighing the filter has been installed on the filter device, to a small amount of reagent water will filter

positioning. Samples taken in the course of moving a magnet stir well, pipette or graduated cylinder to obtain quantitative

amount of water (Note 2) filter. Were at least 20 mL reagent water wash filter 3 times (Note 1) lotion shed and continue

to be pumping about 3 minutes. Remove the disc into the filter in, into the oven to 103 ~ 105 ℃ at least 1 hour after drying,

will be the cooling into the desiccator and weighed. Repeat the preceding drying, cooling, drying and weighing steps,

until the difference in weight before and after the two 0.5 mg range.

(C)Total dissolved solid

If only need determine the total dissolved solid, after passes through the first water sample the glass fiber filter leaf

filtration, its filtrate again depends on seven, steps (one) to carry on the examination, then total dissolved solid.

VIII、Results processing

(A)Total solid(mg/L)=

A:The total solids and the weight of evaporating dish(g)

B:Heavy evaporating dish(g)

V:Sample physical volume(L)

(B)Suspend solid(mg/L)=

C:Suspend solid and Filter weight(g)

D:Filter weight(g)

V:Sample physical volume(L)

(C)Total dissolved solids(mg/L)=Total solid(mg/L)-Suspend solid(mg/L)

or Total dissolved solids(mg/L)=

E:Total dissolved solids and Heavy evaporating dish(g)

B:Heavy evaporating dish(g)

V:Sample physical volume(L)

IX、quality controls

(A)The blank sample is analytical:Every 10 samples or each the batch sample carry out a blank sample to analyze at least,

blank analysis' being worth should be smaller than laws to control 5% of standard value.

(B)Repetitive sample analysis: analysis of each sample must be performed, their relative percent difference should according

to table II of the specification.

X、Accuracy and accuracy

A single laboratory QC samples are 20 repeat analysis, the results as shown in the table

XI、Reference

(A)American Public Health Association,American Water Works Association & Water Pollution Control Federation.

Standard Methods for the Examination of Waterand Wastewater,20th ed. Method 2540B & 2540D ,2-55~58. APHA ,

Washington , D.C , USA , 1998.

(B)Environmental Monitoring System LaboratoryOffice Of Research And Development.U.S. Environmental Protection Agency

Storet No.00530 Method:160.2 Revision 2.0,1993.

Note 1: for of high salt samples (such as water) may, as appropriate, increase the water flush filter of reagents, proposals to

50~150 mL reagent water rinse 3 times.

Note 2: When the sample quantity is bigger than 100 mL, may the graduated cylinder sample, before the sample, the intensive

mixing sample, and pours into fast the sample in the graduated cylinder the quota. If by pipette sample, to obtain the

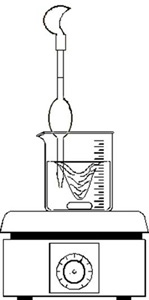

even sample, and the choice choice middle depth (as shown in Figure one) in the eddy current with the container

wall middle place sample.

Note 3: if samples of solid volume is too high, even if reduced sample volume, are not subject to this method to limit the taking of

samples should be less than 200 mg of solid content in demand, should raise notes.

Note 4: for filter 1 l samples when the volume is still not up to 2.5 mg, sample volume can suitably be increased up to 2 litres.

Note 5:classification principles---General inorganic waste liquid treatment of waste.

table one quality control sample ﹡carry on 20 repetition analysis

| Test item | Configuration

value

mg/L | Analysis of

the average

mg/L | Average

recovery rate

(%) | Standard

deviation

mg/L | Accuracy

Accuracy

(RSD)% | Accurate

degree

(X)% |

Total solid

Suspend solid

Total dissolved solids | 200.0

100.0

100.0 | 199.0

96.0

103.0 | 99.5

96.0

103.0 | 0.3

0.6

0.5 | 0.2

0.6

0.5 | 99.3~99.7

95.4~96.6

102.5~103.5 |

﹡QC sample of kaolin and 0.200 0.200 g of g of sodium chloride dissolved in the reagent after water, dilute to 2.0 l,

kaolin by repeated washing, filtering, 105 ° c before drying process step; sodium chloride by 105 ° c before drying treatment.

Table two repetitions analyze opposite difference percentage

| SSExamine scope | Allow opposite difference percentage |

| <25 mg/L | 20% |

| ≧ 25 mg/L | 10% |

Figure a move the liquid tube sampling sketch map